Trylene Inc.

+1 281.835.4162

Email: sales@trylene.com

Our Address

10650 Stancliff Road, Houston, Texas 77099

Services & Solutions

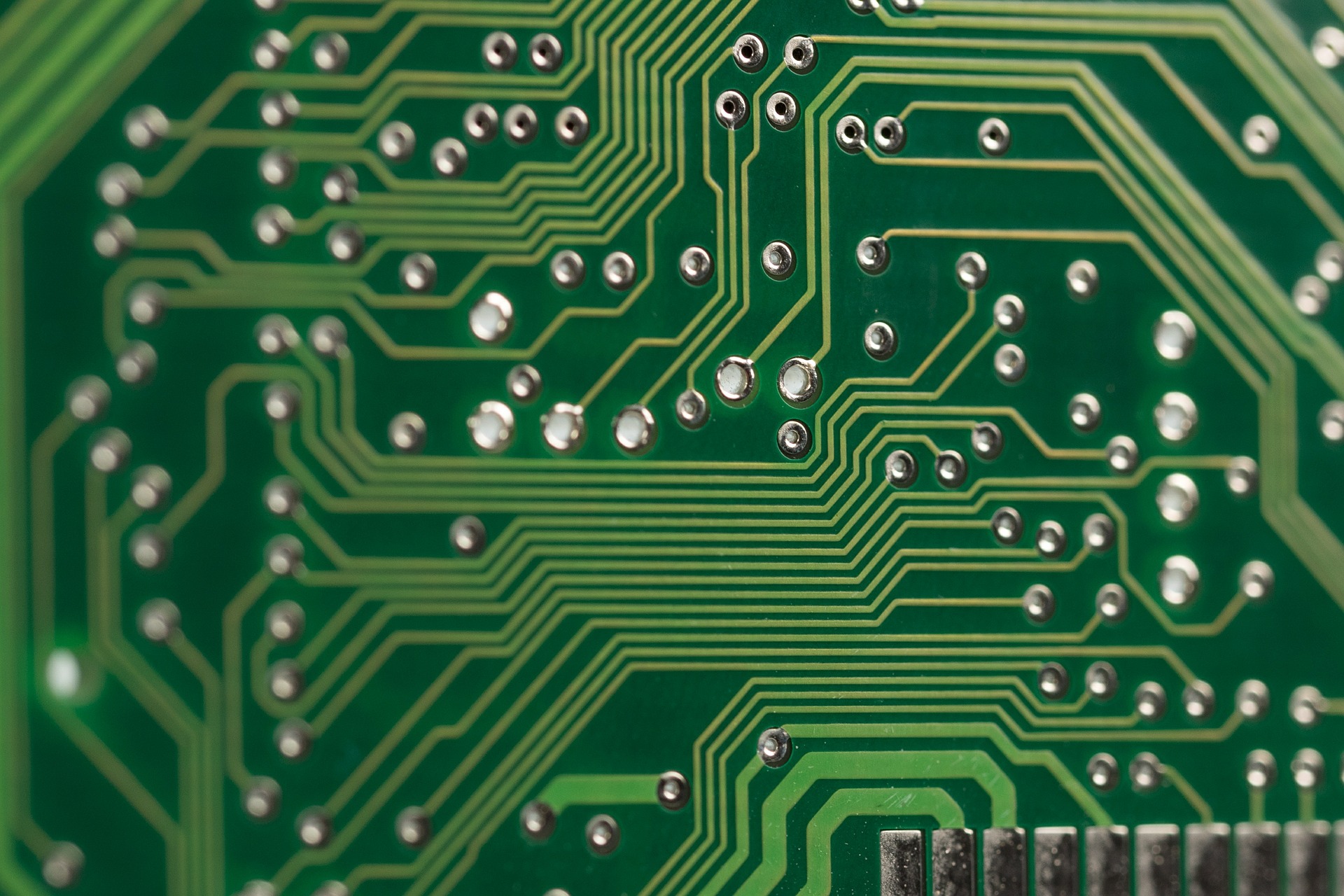

Technology, Speed and Reliability are critical to the success in the electronic industries. We are well equipped with state-of-the-art technologically advanced automated SMT manufacturing line to deliver Technology, Speed and Reliability. Our manufacturing capability covers the wide spectrum of electronic manufacturing and diverse requirements of OEMs. We are flexible in volume, assembly and processes to support today’s complexity in manufacturing. To know more about plant and equipment, please visit INFRASTRUCTURE page.

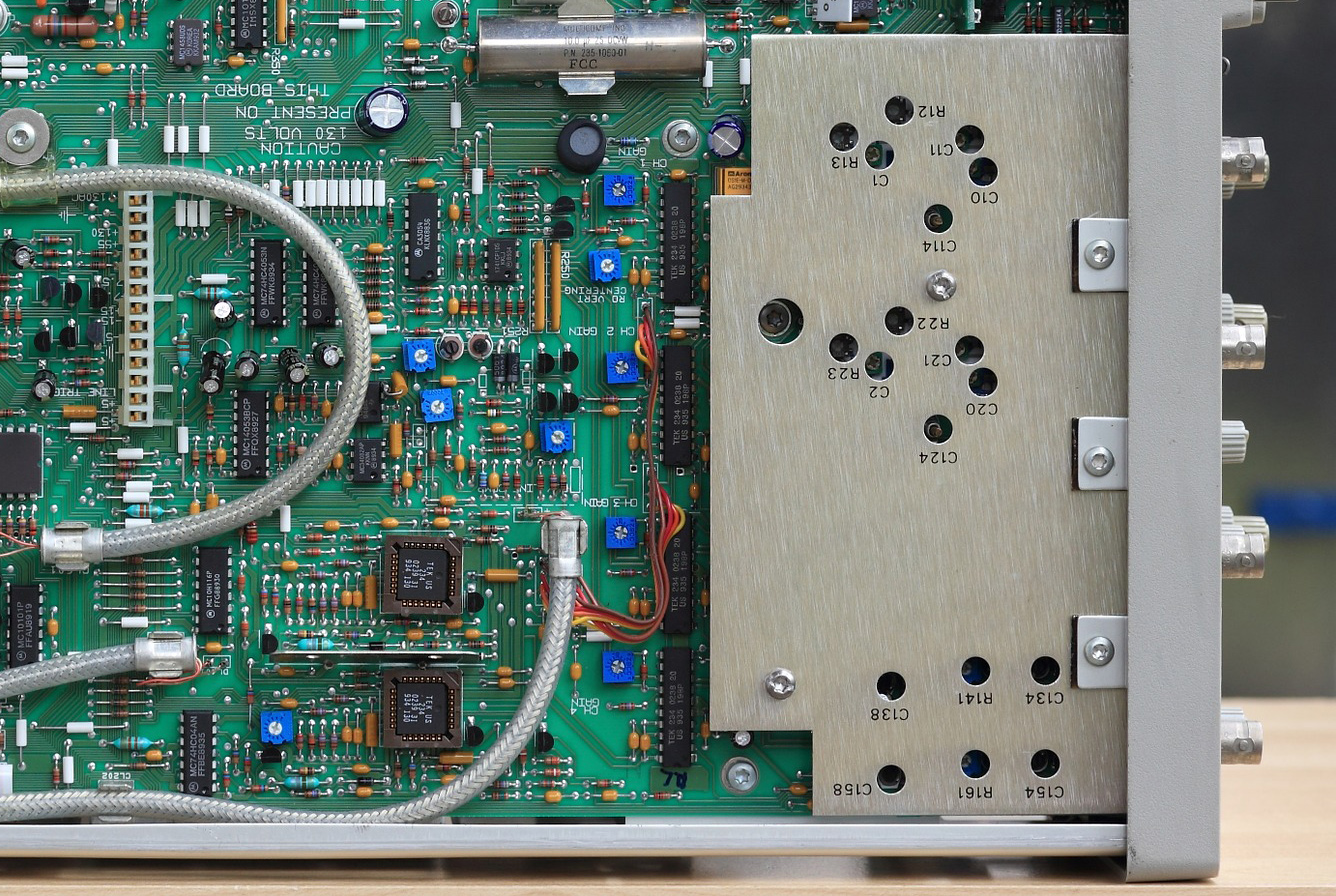

PCB assembly and Turnkey manufacturing are the core offerings from Trylene. Our capability includes

- Surface Mount (SMT) PCB Assembly

- Through Hole PCB Assembly

- Mixed or Complex SMT and Through Hole PCB Assembly

- PBGA (Pitch Ball Grid Array), FBGA (Fine Ball Grid Array), Micro-BGA, CSP, Ultra-fine pitch QFP and QFN

- Fine Pitch (0201 and 01005) components

- Thick/Thin Film

- Through Hole to SMT conversion

- High-Mix and Low-Medium Volume

- Conformal Coating & Epoxy Potting

- Rapid Prototyping

- Turnkey Manufacturing

- Box Build/Final assembly

- Wire and Cable Harnessing

- Board Level or System Level Testing

- Online Quality Control

- Lead Free, RoHS Compliant and Non-RoHS Process

Detailed engineering is the key factor for the success of any new product to enter the market.

While working with the right technical data, time to market and cost are the key parameters which defines the success of the product. Trylene offers end-to-end engineering services right from Concept, Detailed Engineering and Rapid Prototyping to Mass production keeping time to market and cost factors in mind. The concept generation and right layout direction is the deciding factor for any product success and that’s why Trylene works with well experienced and leading mechaninical and electrical engineers to get the things right. Trylene team works efficiently and effectively at every stage of the product life cycle to make sure seamless integration.

Ip Protection

At Trylene, we are committed to protect customer's Intellectually Property (IP) at every stage with highest degree of care. We are ready to sign NDA and MOU with customers to make sure that we are equally responsible to protect customer’s IP. We also sign NDA with all employees and with trusted partners we work during the process. We have a system in place against IP leakages and only limited access given to the right people those who only need to know and are working on the project.

Integrated Engineering Services offerings...

Electronic System - Engineering Services

- Hardware Platform Selection

- Hardware Schematic Engineering Support

- ECAD- PCB Engineering Support

- Embedded Software Support

- Rapid Prototyping

- Signal Integrity & Measurements

- Regulatory Compliance

- Testing & Certification

Mechanical Support & Engineering Services

(Plastic & Metal Enclosures, Parts and Components)

- Market Research & Bench-marking

- Concept Generation

- Concept Refinement

- Detailed Mechanical Engineering

- Failure Mode Effect Analysis (FMEA)

- Engineering Support for Manufacturability and Reliability (DFx)

- Rapid Prototyping

- Verification and Validation

- Environmental and Endurance Testing Support

- Tool Development Support

- Manufacturing Support

Rapid prototyping is very important in terms of time to market, product refinement, optimization and validation before entering into mass production. Rapid prototyping and small batch prototypes give chance to test, validate and realize the engineering data. It helps in enhancing product quality and performance, eliminate any engineering defects. It also allows carrying out Failure Mode Effect Analysis (FMEA) and DFx refinement.

Rapid Prototyping Services includes

- Quick Turn PCB fabrication

- Component Kit Sourcing

- Strategic AVL & Parts Management

- Quick Turn PCB Assembly

- Plastic Parts Prototype by SLS, SLA, FDM, CNC and 3D printing

- Metal Parts Fabrication

- Product Assembly

- FMEA and DFx Reports

- Support on Test Development

- Analysis and Review Reports for Customers' Layout Refinement

New Product Introduction (NPI) plays very important role in optimizing new products time to market and time to volume production. NPI bridges the gap between prototypes and regular volume production. Trylene’s technology, engineering and manufacturing expertise helps OEMs to take new products to the market cost-effectively and timely. The process refines the manufacturing process and sets optimized parameters.

We understand customer’s expectations, requirements and vision of launching new product successfully in the market. We also provide feedback to improve product quality and manufacturability. The engagement starts from early prototype phase, focuses on pilot production runs and ends at product handover to volume production.

New Product Introduction (NPI) Strategy

- Quick Turn RFQ Management for Pilot Production

- Prototype Report Analysis and Refinements

- Minimum Cycle Time for Pilot Production

- Part Selection and Obsolesce Management

- Alternate Part Management

- AVL Management

- Pilot Production Component Sourcing Support

- Defining Assembly Time and Set up Parameters

- Test System Refinement Support

New Product Introduction (NPI) plays very important role in optimizing new products time to market and time to volume production. NPI bridges the gap between prototypes and regular volume production. Trylene’s technology, engineering and manufacturing expertise helps OEMs to take new products to the market cost-effectively and timely. The process refines the manufacturing process and sets optimized parameters.

We understand customer’s expectations, requirements and vision of launching new product successfully in the market. We also provide feedback to improve product quality and manufacturability. The engagement starts from early prototype phase, focuses on pilot production runs and ends at product handover to volume production.

New Product Introduction (NPI) Strategy

- Quick Turn RFQ Management for Pilot Production

- Prototype Report Analysis and Refinements

- Minimum Cycle Time for Pilot Production

- Part Selection and Obsolesce Management

- Alternate Part Management

- AVL Management

- Pilot Production Component Sourcing Support

- Defining Assembly Time and Set up Parameters

- Test System Refinement Support

It is essential to upgrade products and to reduce cost to remain competitive in the market. We provide Value Engineering services to enhance product features, performance, quality, looks and to reduce the BoM cost. We can get engaged in the following areas

- BoM Analysis

- Cost Reduction through Alternate Vendor Selection

- Cost Reduction through Alternate Component Selection and Sourcing

- Cost reduction through Alternate Material Selection

- Custom Made LCDs, Capacitive Touch Panels, Cables, Parts, Components and Assembly Development

- Strategic Component & Vendor Selection and Qualification

- Metal enclosure to Plastic conversion to enhance Look and achieve Cost Reduction

- Through Hole PCB to SMT PCB Conversion

- Alternate Composition Modification Support

- Component Obsolesce Resolution

- Complete Product Revamping

- Incorporating New Technologies

- Sourcing of Hard to find Components

The supply chain strategy and management have become very crucial to satisfy customers in terms of right product, at right price, on the right time and to the right place. The core driving parameters which define the success are quality, cost, delivery and service. Trylene’s capability to manage and ability to deliver as per strategy makes OEMs life easy.

Our goal is to roll out strategy which is aligned with customer’s supply chain objective and to manage it efficiently and effectively. We can contribute hugely in

- Production Planning

- Raw Materials Planning

- Forecasting

- Purchase Ordering

- Delivery Acknowledgment

- Delivery Planning and Traceability

- Lead Time Reduction through Vendor Process Analysis and Vendor Managed Inventory

- Quality Improvement through Process Refinement at Vendor’s place

- Cost Reduction through Negotiation & Alternate Part or Vendor Development

- Cost Reduction through Shipment Consolidation

- Incoming Quality Check and Quality Plan

- Inventory Management

- Supply Chain Risk Analysis

- Small Batch Procurement and Production for Prototypes and Pilot Run

- Single Layer PCB

- Double Sided PCB

- Multi-layer PCB

- Rigid PCB

- Flexible PCB (FPC)

- Rigid Flex PCB

- HDI

- White

- Yellow

- Black

- Red

- Normal Tg FR4

- High Tg FR4

- Rogers

- Getek

- Aluminium

- Immersion Tin

- Immersion Gold

- Immersion Silver

- Lead-free HASL

- OSP

- Gold Flash

- Gold Finger

- Green

- Black

- Red

- Blue

- White

- Yellow

- Blind and Buried Vias

- Impedance Control

- Line and Spaces (Volume 3/3mils, Prototype 2/2mils)

- Minimum Drill > 0.2mm

- Early Engagement in Product Engineering & Development

- Product Layout Verification Support for Manufacturability

- Tooling Vendor Identification and Qualification Support

- Cost Comparison and Analysis

- Mold and Part Verification Support

- Production Support & Part Supply

- Engineering Injection Molds

- Automotive Injection Molds

- White Goods Injection Molds

- In-Mold Labelling (IML) & In-Mold Decoration (IMD) Molds

- Painting

- Screen Printing & Pad Printing

- Chrome Plating

- UV Printing

- Hot Stamping

- Custom and Proprietary Metal Enclosures

- Engineering Support for Manufacturability

- Quick Prototype Building by using difference advanced technologies like Laser and Waterjet cutting

- Quick Tooling

- Small batch production support

- Surface treatment: Plating, Powder Coating & Painting

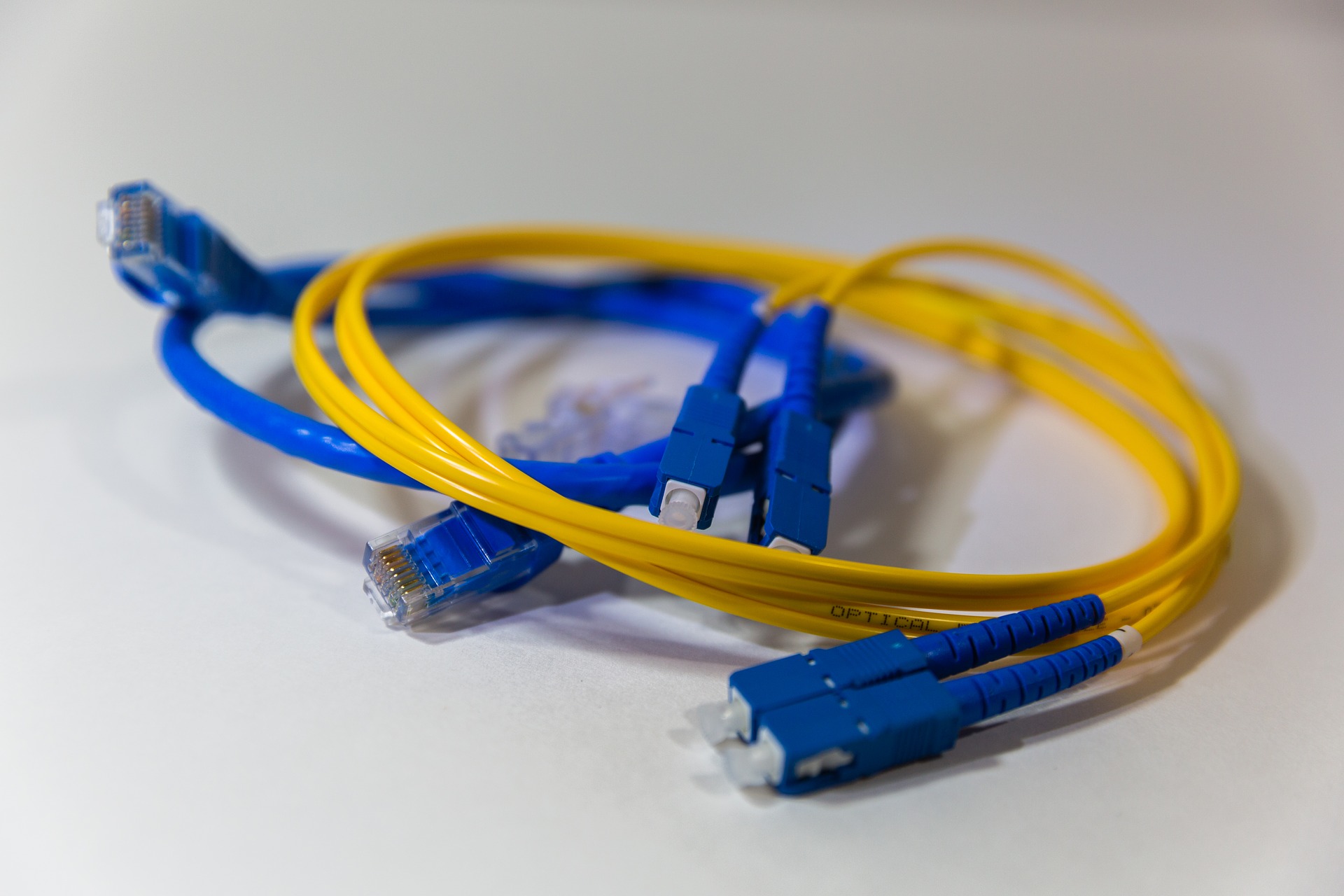

- Wire Harnesses

- Molded Cable Assemblies

- Complex Cable Assemblies

- Custom or Application Specific Assemblies

- Interconnection

- Electro-mechanical Assemblies

- Power Cable Assemblies

- RF Cable Assemblies